# CLASSIFICATION OF COMBUSTION CHAMBER:

Table of Contents:

- What Is Combustion Chamber?

- Classification Of Combustion Chamber

- Can Type Combustion Chamber

- Cannular Type Combustion Chamber

- Annular Type Combustion Chamber

- Double Annular Type Combustion Chamber

- Comparison Diagram

What Is Combustion Chamber?

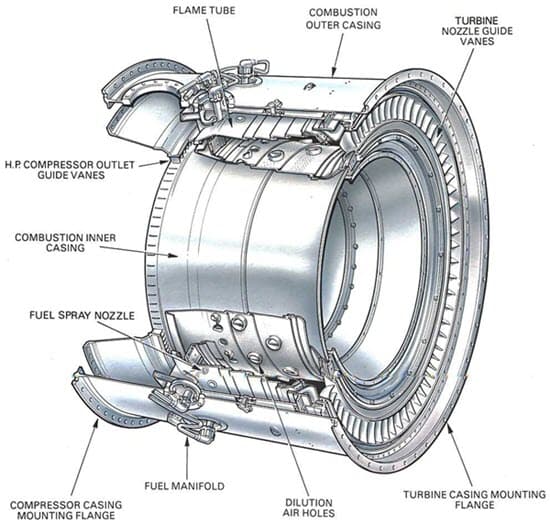

A combustion chamber is a component or area of a gas turbine, ramjet, or scramjet engine where combustion takes place. It is also known as a burner, combustor or flame holder. In a gas turbine engine, the combustor or combustion chamber is fed high pressure air by the compression system. The combustor then heats this air at constant pressure. After heating, air passes from the combustor through the nozzle guide vanes to the turbine. In the case of a ramjet or scramjet engines, the air is directly fed to the nozzle.

Classification Of Combustion Chamber:

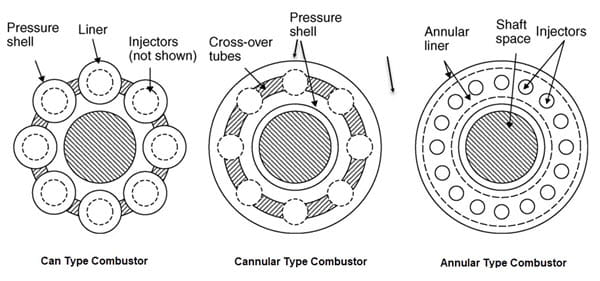

The combustion chamber can be classified as three types and are below,

- Can Type Combustor

- Cannular Type Combustor

- Annular Type Combustor

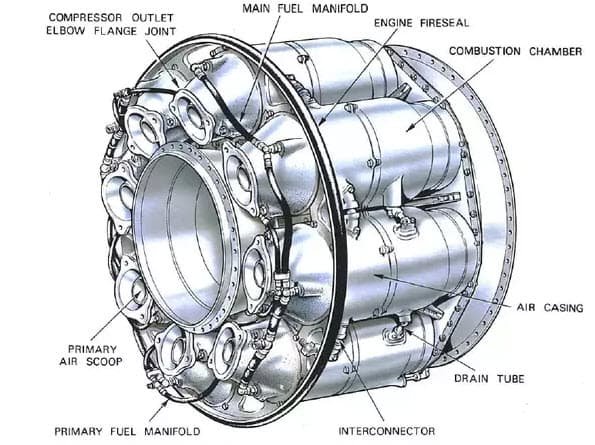

1. Can Type Combustion Chamber:

- Can combustors are self-contained cylindrical combustion chambers.

- Each “can” has its own fuel injector, igniter, liner, and casing.

- The primary air from the compressor is guided into each individual can, where it is decelerated, mixed with fuel, and then ignited.

- The secondary air also comes from the compressor, where it is fed outside of the liner (inside of which is where the combustion is taking place).

- The secondary air is then fed, usually through slits in the liner, into the combustion zone to cool the liner via thin film cooling.

- In most applications, multiple cans are arranged around the central axis of the engine, and their shared exhaust is fed to the turbine(s).

- Can type combustors were most widely used in early gas turbine engines, owing to their ease of design and testing (one can test a single can, rather than have to test the whole system).

- Can type combustors are easy to maintain, as only a single can needs to be removed, rather than the whole combustion section.

- Most modern gas turbine engines (particularly for aircraft applications) do not use can combustors, as they often weigh more than alternatives.

- Additionally, the pressure drop across the can is generally higher than other combustors (on the order of 7%).

- Most modern engines that use can combustors are turbo-shafts featuring centrifugal compressors.

- Well suited to engines with centrifugal compressors, where the flow is divided into separate streams in the diffuser.

- Easier development (could be carried out on a single can using only a fraction of the overall airflow and fuel flow).

- Increased volume, weight and frontal area.

- Increased Pressure drop (more surface area in contact with air/gas).

Can Type Combustor – Classification of Combustion Chamber

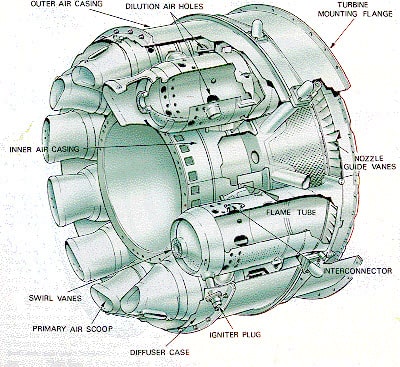

2. Cannular Type Combustion Chamber:

- Cannular type combustor can be called as can annular type combustor.

- Like the can type combustor, can annular combustors have discrete combustion zones contained in separate liners with their own fuel injectors.

- Unlike the can combustor, all the combustion zones share a common ring (annulus) casing. Each combustion zone no longer has to serve as a pressure vessel.

- The combustion zones can also “communicate” with each other via liner holes or connecting tubes that allow some air to flow circumferentially.

- The exit flow from the cannular combustor generally has a more uniform temperature profile, which is better for the turbine section.

- It also eliminates the need for each chamber to have its own igniter. Once the fire is lit in one or two cans, it can easily spread to and ignite the others.

- This type of combustor is also lighter than the can type, and has a lower pressure drop (on the order of 6%).

- However, a cannular combustor can be more difficult to maintain than a can combustor.

- An example of a gas turbine engine utilizing a cannular combustor is the Rolls-Royce Tay turbofans use this type of combustor as well.

Cannular Type Combustor – Classification of Combustion Chamber

3. Annular Type Combustion Chamber:

- Annular combustors do away with the separate combustion zones and simply have a continuous liner and casing in a ring (the annulus).

- There are many advantages to annular combustors, including more uniform combustion, shorter size (therefore lighter), and less surface area.

- Additionally, annular combustors tend to have very uniform exit temperatures. They also have the lowest pressure drop of the three designs (on the order of 5%).

- The annular design is also simpler, although testing generally requires a full size test rig.

- An engine that uses an annular combustor is the CFM International CFM56.

- Most modern engines use annular combustors; likewise, most combustor research and development focuses on improving this type.

Annular Type Combustor – Classification of Combustion Chamber

Double Annular Type Combustion Chamber:

- One variation on the standard annular combustor is the double annular combustor (DAC).

- Like an annular combustor, the DAC is a continuous ring without separate combustion zones around the radius.

- The difference is that the combustor has two combustion zones around the ring; a pilot zone and a main zone.

- The pilot zone acts like that of a single annular combustor, and is the only zone operating at low power levels.

- At high power levels, the main zone is used as well, increasing air and mass flow through the combustor.

- GE’s implementation of this type of combustor focuses on reducing NOx and CO2 emissions.

- Extending the same principles as the double annular combustor, triple annular and “multiple annular” combustors have been proposed and even patented.

Classification Of Combustion Chamber – Comparison Diagram:

Plz upload more details about aircraft structure, loads and stability of aircraft, UAV, Aircraft wing and fuselage details. Plz

Hello Sundarapandi, Thank you for reaching out to us. We will upload those notes soon.