# GAS TURBINE:

Table of Contents:

- What Is Gas Turbine?

- Operating Principles

- Thermodynamic Processes of Gas Turbine Engine

- Types of Gas Turbines Based On Structure and Function

Turbo Jet Engine

Turbo Fan Engine

Single-Shaft Gas Turbine Engine

Double-Shaft Gas Turbine Engine - Advantages

- Disadvantages

What Is Gas Turbine?

A gas turbine, also called a combustion turbine, is a type of internal combustion engine. It has an upstream rotating compressor coupled to a downstream turbine, and a combustion chamber in-between.

- The compressor, which draws air into the engine, pressurizes it, and feeds it to the combustion chamber at speeds of hundreds of miles per hour.

- The combustion chamber, typically made up of a ring of fuel injectors that inject a steady stream of fuel into combustion chambers where it mixes with the air. The mixture is burned at temperatures of more than 2000 degrees F. The combustion produces a high temperature, high pressure gas stream that enters and expands through the turbine section.

- The turbine is an intricate array of alternate stationary and rotating aerofoil-section blades. As hot combustion gas expands through the turbine, it spins the rotating blades. The rotating blades perform a dual function: they drive the compressor to draw more pressurized air into the combustion section, and they spin a generator to produce electricity.

Operating Principles:

Thermodynamic Processes Of Gas Turbine Engine:

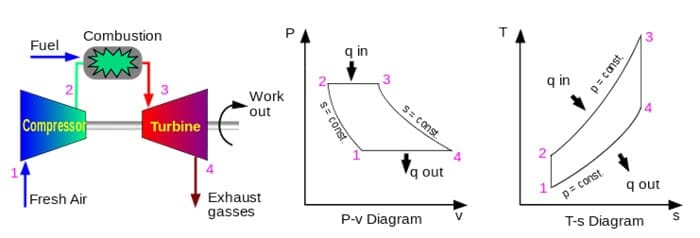

Gases passing through an ideal gas turbine undergo three thermodynamic processes. They are,

- Isentropic compression

- Isobaric (constant pressure) combustion

- Isentropic expansion

Together, these make up the Brayton cycle.

In a practical gas turbine, gases are first accelerated in either a centrifugal or axial compressor. These gases are then slowed using a diverging nozzle known as a diffuser; these processes increase the pressure and temperature of the flow. In an ideal system, this is isentropic. Gases then pass from the diffuser to a combustion chamber, or similar device, where heat is added. In an ideal system, this occurs at constant pressure (isobaric heat addition).

As there is no change in pressure the specific volume of the gases increases. Finally, this larger volume of gases is expanded and accelerated by nozzle guide vanes before energy is extracted by a turbine. In an ideal system, these gases are expanded isentropically and leave the turbine at their original pressure.

Types of Gas Turbines Based On Structure and Function:

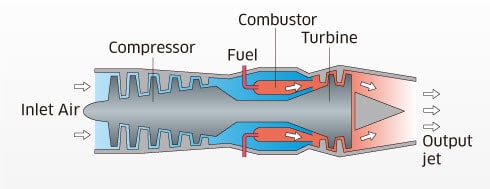

1. Turbo Jet Engine:

This is the most basic type of gas turbine for obtaining thrust using a jet flow, and the simplest in terms of structure. This engine is suitable for aircraft which fly at high speed, and is used in supersonic airliners and jet fighter planes.

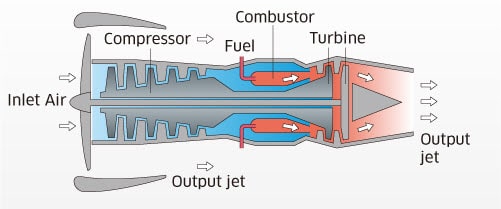

2. Turbo Fan Engine:

With this type, a separate turbine is placed after the turbo jet engine, and this turbine operates a large fan at the front of the engine. This fan increases the air flow rate and boosts thrust. This type has a low noise level, and low fuel consumption at subsonic speeds, so today this type of gas turbines is used almost exclusively as airliner engines.

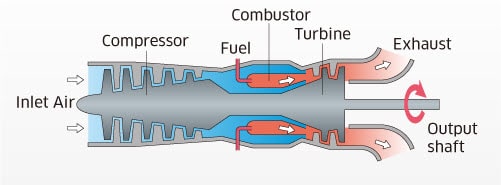

3. Single-Shaft Gas Turbine Engine:

This gas turbine delivers output as rotational force, and the turbine and compressor are coupled by a single shaft. Part of the turbine output is used to drive the compressor, and the remainder is delivered to the output shaft. This type is suitable for applications, such as alternator drives, requiring rotation at constant speed.

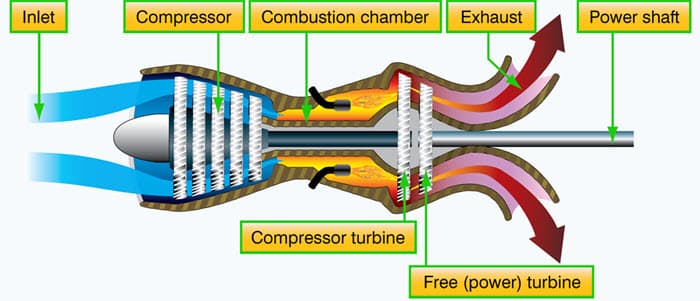

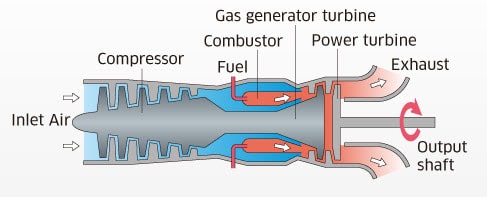

4. Double-Shaft Gas Turbine Engine:

In this type, a separate turbine is placed after the gas generator turbine, and the energy of the jet blast is delivered as rotational force. This rear turbine is called the power turbine. Since there is no mechanical coupling between the power turbine shaft and the compressor shaft, it is possible to select any output rotation speed. This is suitable for driving equipment with a wide range of rotation speeds. This type is widely used in propeller planes and helicopters, and in applications such as pump/compressor drive, ship main engines, and generator drive.

Advantages:

- Gas turbine engines have a great power-to-weight ratio compared to reciprocating engines. That is, the amount of power you get out of the engine compared to the weight of the engine itself is very good.

- Gas turbine engines are smaller than their reciprocating counterparts of the same power.

Disadvantages:

- Compared to a reciprocating engine of the same size, they are expensive.

- Because they spin at such high speeds and because of the high operating temperatures, designing and manufacturing gas turbines is a tough problem from both the engineering and materials standpoint.

- Gas turbines also tend to use more fuel when they are idling, and they prefer a constant rather than a fluctuating load.